5G Transformation Hub

5G-Enabled factory of the future

Using 5G as an alternative to Wi-Fi in smart factories

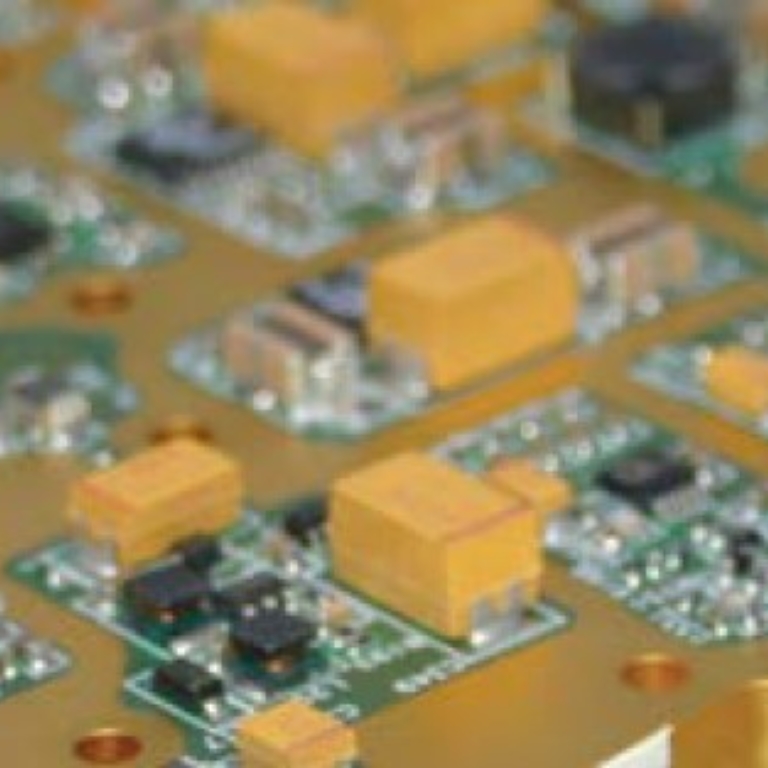

To realise the potential of 5G connectivity to enhance precision and flexibility in smart manufacturing, primarily via AI-driven analytics capabilities, ST Engineering, a global technology, defence and engineering group, has developed Heterogeneous Integration (HI), composed of integrated circuits enclosed in chip carrier packages, connected internally by fine wires bonded to the package, that can be stacked vertically or tiled horizontally - capable of delivering optimal 5G connectivity performance in a compact footprint and enabling advanced connected solutions smart factory settings.

Select a project

Contents

Challenge

Most current manufacturing processes are extremely resource intensive and time consuming, often consisting of operation `islands’ and tightly coupled with intensive manual visual inspections, and 24/7 operation is generally not feasible. Prevalent network bandwidth limitations and latency response times, however, place considerable limitations on the ability to automate these processes effectively or to reallocate human duties to connected machines.

Solution

Autonomous mobile 5G robots are used to seamlessly chain the series of operations required to produce HIs with maximum efficiency. Build-to-print HIs can be ensured that material kitting and tool changing can be constantly serviced, while build-to-spec HIs can be guarded against errors during manufacturing. Machine vision can be used for rapid decisions; computer vision for quality scoring, with video analytics (VA) and machine learning (ML); intelligent automation (IA) for materials orchestration and tool loading without human intervention; and augmented reality (AR) for collaboration and training. Factory and machine sensors can be managed via an IoT platform based on 5G and MEC.

Impact & Statistics

Intelligent automation (IA) via 5G pivot aims to attain first-pass yield rates of 95% or higher. Reduction of waste from rejection of mishandled processes are avoided via precision robotics. Production throughput stands to increase by threefold, with full machine utilisation and overall equipment effectiveness maintaining at a high level. Manpower can be redeployed towards higher-skill requirements, supported by highly customisable, reconfigurable and connected work cells.

Wider Implications

his use case has potential for adoption beyond manufacturing, with potential to be applied across healthcare, transportation, and logistics. ST Engineering is also ooking into expanding their global footprint, by bringing their 5G-Enabled Lights-Out Factory of the Future to other parts of the region, as well as other ST Engineering business units, which is likely to result in greater efficiencies across their global manufacturing capability.

Stakeholders

IMDA and ST Engineering

02

Using 5G as an alternative to Wi-Fi in smart factories

5G offers numerous advantages over conventional wireless connectivity

Wi-Fi is unlicensed and open to interference, and can suffer from congestion issues when large data transfers occur and user numbers increase. It is also prone to creating spaces with weak signal strengths which cannot be used for machines that require constant connectivity, and Wi-Fi repeaters are not reliable as the signal strengths tend to fluctuate. 5G helps achieve the goal of a smart factory:

Smart sensors and visual analytics

5G will play an essential role in the automation of the highly complex process of Heterogeneous Integration (HI), including traditional PCB manufacturing processes, thereby achieving high reliability and high output efficiency with lights-out operations. To achieve a fully smart and automated factory, ST Engineering needs a high degree of flexibility in their manufacturing processes. This is enabled through wireless workstations, which facilitate easy reconfiguration of dynamic production environments, and future factories will deploy video analytics and intelligent sensors to optimise and orchestrate these end-to-end processes for manufacturing.

Digital twins

The added flexibility of digital twinning allows ST Engineering to add and test new features and provide this as a service to customers and suppliers - mapping out their physical assets in a virtual space allows for highly customisable products and numerous other ways to add value. Being fully connected, these digital twins enhance real-time interaction for internal and external parties involved.

Intelligent robotics

ST Engineering’s vision is to transform their current manufacturing into an Industry 4.0 facility with an advanced 5G network - they continue to implement intelligent sensors that capture workflows, and autonomous mobile robots (AMR) to manage facilities across two different sites.

AR/VR

Mixed reality technologies like AR/VR are an example of the transformation made possible by 5G to help real-time communication become seamless, easier and more effective. This supports advanced training and remote technical assistance, and also collaboration between staff to improve factory automation and planning decisions.

In ST Engineering’s journey towards Industry 4.0, they aim to be the first to achieve a fully autonomous (i.e. unmanned onsite) factory within the region.

03

Enabling automated robotics and inspection

5G accelerates mobility and reduces error

From manual inspection to fully automated inspection

The plant is currently semi-automated, with workstations like visual inspection, material handling and component reading done manually.

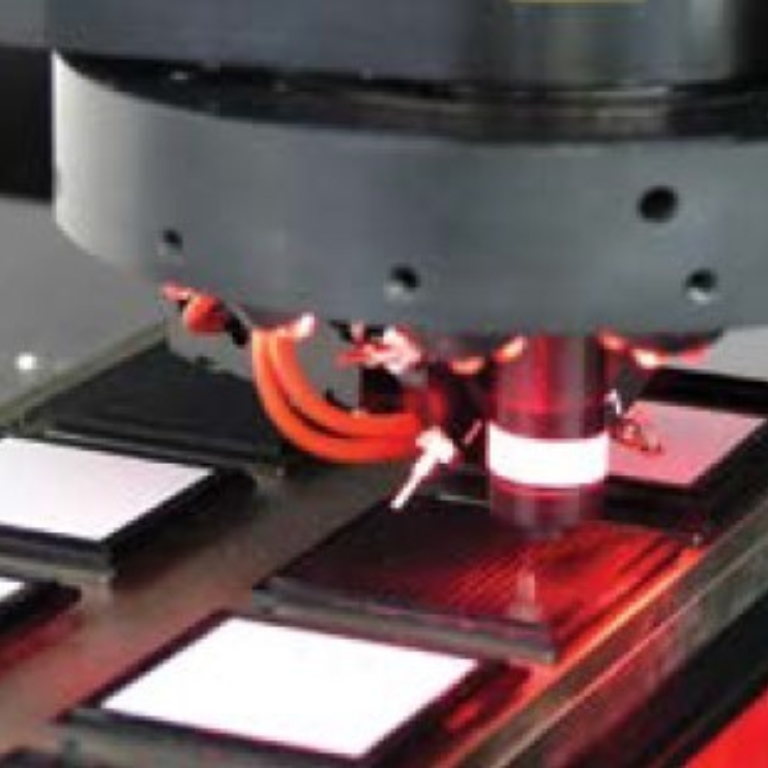

A.I. cameras can be used to detect defects in HIs. The very small size of HI structures present significant challenges for manual inspections - the process is both time-consuming and labour-intensive.

With visual analytics, the inspection of HIs becomes much faster and more accurate, while deploying of

AI-assisted automation also greatly reduces manual work and human error.

From hand carry to autonomous mobility robot

Materials are often carried by hand from one workstation to another - the introduction of AMRs will greatly assist in transportation of goods in the plant, which will be critical in a dynamic manufacturing environment.

04

Achieving higher quality and greater consistency

The foundations of continuous and consistent production

Continuous production as a contingency

Tight labour supply has always made hiring operators and technicians difficult. This lack of labour and skill has been made even more severe by the covid pandemic, affecting production. With fully automated processes, ST Engineering can become less reliant on manpower.

High consistency and quality output

Automation allows ST Engineering to achieve higher quality and consistency by eliminating human error during inspections. ST Engineering are now expecting an ROI of $62m, or 34.4% savings over 5 years after implementation, based on the assumption of higher output, less wastage and lower manpower to sustain additional shifts, with the following KPIs:

-

Keeping operations running 24/7, higher revenue is expected with projected CAGR growth of 7% estimated in the next 5 years

-

With the implementation, ST Engineering hope to achieve higher productivity of 50% with increased automation

-

There are also other intangible outcomes from this implementation - e.g. ST Engineering will also train and upskill operators to perform higher-value tasks such as fleet monitoring and basic analytics for early prevention, and intervention in breakdown of machinery

Solution offers major advantage to other businesses

The project has shown a number of applications that can be applied to other organisations:

-

Optimise efficiency and quality with AI/ML and analytics

-

Automation of processes with robots for improved productivity

-

Contactless remote operation as a contingency during lockdown or disruptions

-

Managing tight labour supply and aging workforces

-

Improved customer satisfaction

05

Future plans

Only the beginning for industrial 5G

Enhancement of digital twin model

The digital twin model can be developed to simulate a real-time factory setup for various different requirements – it will be extended to serve needs not only within the organisation, but also those of customers, to help ST Engineering better understand and interact with those their products serve.

AR glasses to support future collaboration

AR smart glasses also open opportunities for closer collaboration with overseas manufacturers and customers, helping to increase customer acquisition and retention. Through more complex yet flexible manufacturing processes, ST Engineering can engage with customers earlier to design and simulate products, allowing them to visualise and dynamically reconfigure the manufacturing plant and processes accordingly.

06

About

About the GSMA

The GSMA is a global organisation unifying the mobile ecosystem to discover, develop and deliver innovation foundational to positive business environments and societal change. Our vision is to unlock the full power of connectivity so that people,

industry, and society thrive. Representing mobile operators and organisations across the mobile ecosystem and adjacent industries, the GSMA delivers for its members across three broad pillars: Connectivity for Good, Industry Services and Solutions, and Outreach. This activity includes advancing policy, tackling today’s biggest societal challenges, underpinning the technology and interoperability that make mobile work, and providing the world’s largest platform to convene the mobile ecosystem at the MWC and M360 series of events.

For more information, please visit the GSMA corporate website at www.gsma.com.

Follow the GSMA on Twitter: @GSMA.

GSMA 5G Transformation Hub

The GSMA 5G Transformation Hub is a source of information on some of the most innovative 5G solutions in the world. This portal contains case studies detailing design, benefits, key players, measured value and the future impact of scaling up these 5G solutions worldwide. The 5G Era is now firmly established and this family of standardised GSM technologies, including mmWave, are being rolled out successfully across the globe. The GSMA 5G Transformation Hub, launched at MWC Barcelona in 2022, provides details of how 5G is best placed to deliver real value for a range of key sectors including manufacturing, energy, transportation, media and live entertainment, smart cities and construction.. Many more case studies will be added, in the coming months, covering even more industries and the GSMA is asking Members to nominate innovative 5G case studies to add to this global digital showcase. The 5G Transformation Hub and this particular Case Study are both sponsored by Qualcomm.

About this case study

This case study is for information only and is provided as is. The GSM Association makes no representations and gives no warranties or undertakings (express or implied) with respect to the study and does not accept any responsibility for , and hereby disclaims any liability for the accuracy or completeness or timeliness of the information contained in this document. Any use of the study is at the users own risk and the user assumes liability for any third party claims associated with such use.