5G Transformation Hub

Ultra-reliable 5G ushers in a new era for mining

China Unicom plans to install private 5G networks in more than 100 mines

The Yanjiahe Coal Mine in the Shanxi province of China is using a 5G private network and edge compute nodes to monitor all the major mining operations, boosting efficiency, reducing safety-related risks, and promoting sustainable development of the industry.

Select a project

Contents

Challenge

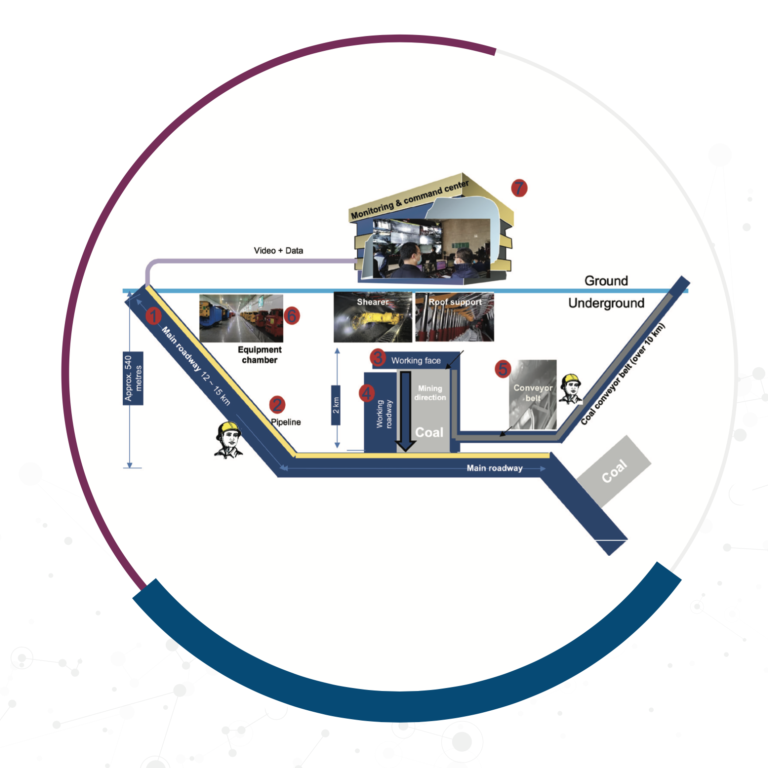

Safety is critical in all mining operations. Workers underground are exposed to a wide range of risks, from explosions to structural failures, gas poisoning, and extreme heat and humidity levels. But it is generally difficult to monitor underground devices and personnel. For instance, the main haulage passage may span hundreds of kilometres, making it difficult to monitor the long conveyor belts. As a result, routine equipment maintenance is labour-intensive and time-consuming, crippling work efficiency.

Solution

Shanxi Xiangning Coke Coal Group, together with China Unicom Industrial Internet (Shanxi) and Huawei, deployed a 5G private network in October 2021 in the Yanjiahe Coal Mine. The network can transfer videos captured by connected HD cameras underground to the equipment room above ground for content analysis and risk identification. The 5G network is supported by edge compute facilities within the mine. If the local user plane fails, an emergency control plane at the edge can take over.

Impact & Statistics

Compared with the complex cabling it replaced, the 5G private network solution is easy to deploy and more reliable. The 5G-enabled device inspection reduces the workload of personnel at mines, while the remote control of mining vehicles keeps workers away from underground dangerous areas. For example, the Xinyan Coal Mine in the Shanxi province has been able to halve the number of staff working at the mining face to 65

Wider Implications

The innovative solution employed by Yanjiahe Coal Mine points to how enterprises can harness highly-reliable and secure private 5G networks that can perform mission-critical tasks. By enabling automation and improving safety, such networks could improve efficiency and productivity in a wide range of industries, including the oil, gas and chemicals sectors.

Stakeholders

Yanjiahe Coal Mine of Shanxi Xiangning Coke Coal Group, China Unicom, China Unicom Industrial Internet (Shanxi), Huawei

02

Ultra-reliable 5G ushers in a new era for mining

China Unicom plans to install private 5G networks in more than 100 mines

Historically, mining has been both dangerous and difficult. Working underground is fraught with both health and safety hazards and logistical challenges.

The Yanjiahe mine uses its private 5G network to transfer videos captured by connected cameras underground to the equipment room above ground for content analysis and risk identification. The mine has installed 5G HD cameras around the tunnelling devices, transportation transfer points, and vehicle yards.

The 5G network has the capacity to support HD video streams from large numbers of cameras. Huawei estimates between 30 and 50 cameras are required to monitor a 2 km long roadway, while a 10 km conveyor belt requires approximately 50 to 100 cameras. As a result, the 5G network needs to provide an uplink capacity of 100 Mbps every 200 metres.

Once the video streams are transferred, the mine’s video content analysis system can quickly identify safety risks on coal conveyor belts, such as belt misalignment, large or stacked coal pieces on the belts, and personnel on the belts. It then generates alarms so that these risks can be resolved immediately. The mine is also employing 5G-connected gas and water sensors to monitor the environmental conditions in real time and alert the workers in the case of leaks.

Huawei says 5G connectivity is capable of supporting more than 10,000 underground sensors within a single mine, enabling the monitoring of the roof bed separation every 10 meters, and environmental parameters every 50 meters, as well as the performance of the mining equipment.

At the Yanjiahe mine, the private 5G network is being used to improve efficiency and productivity, as well as safety. It enables automatic inspection of underground electromechanical devices, such as the conveyor belt, relieving workers from labour-intensive and error-prone manual inspections, while significantly improving efficiency. As well as employing HD video cameras, inspection robots can use thermal imaging systems and sound detection technology to monitor how well machines are running. The 5G connectivity is also sufficiently responsive to enable the remote control of road headers and mining vehicles, facilitating unmanned underground operations.

Mines can struggle to recruit people to work underground, given the wide range of risks, from explosions to structural failures, gas poisoning, and extreme heat and humidity levels. Faults in the mining, excavation, ventilation, electromechanical systems, drainage, power supply, and transportation systems can result in severe accidents. Huawei says the average age of workers in mines in China is now 42, as young people are reluctant to work underground.

03

The 5G network is designed to deliver high levels of reliability

Prior to the arrival of 5G, mines struggled to install adequate communications systems. Huawei says 4G and Wi-Fi networks cannot meet the performance requirements, and are unable to simultaneously offer deployment flexibility and network quality.

In Yanjiahe Coal Mine, the new 5G network has replaced the optical fibre network previously used for the work and excavation. “Conventional wired networks are not that reliable for underground communications as network cabling is rather complex and the cables are vulnerable to moisture and corrosion in mines,” explains [Chen Dan – 5G Industry Director of China Unicom 5G B2B Dept.]

In addition, underground environments can be very complex. For instance, the main haulage passage may span hundreds of kilometres, so it can be difficult to monitor the operating status of equipment, such as long conveyor belts. This makes routine equipment maintenance labour-intensive and time-consuming, crippling work efficiency.

Mining enterprises have high network reliability requirements to enable continuous operations even in extreme situations. For this purpose, a conventional 5G private network is inadequate, according to Huawei. “In a conventional 5G private network, only the user plane is deployed in edge compute on-site,” explains [Hu Chunzhe, VP of Huawei Cloud Core Network Marketing Dept.]. “If the user plane is disconnected from the public control plane of the 5G core, services will be taken down.”

To address this challenge, the 5G network in the Yanjiahe Coal Mine utilises an “on-premises emergency 5GC control plane”, which is deployed on-site. If the local forwarding plane fails to communicate with Unicom’s public control plane, the emergency control plane can take over services immediately to ensure production continuity. The emergency control plane can process new service requests and allow new access from various 5G devices.

This fall-back ensures that the core production systems at the mines can keep running smoothly. Huawei and Unicom have named the resulting solution Kite-Like PNI-NPN (public network integrated non-public network).

The Yanjiahe Coal Mine 5G network is also supported by edge compute nodes on-site. That means all the data it captures can be processed locally – there is no need for data to be sent to China Unicom's public network.

The base stations, mobile phones, and other connected sensors underground are designed to be explosion-proof. That ensures the network is sufficiently reliable to monitor all the operations and devices, such as excavation and belt conveyors.

Hu Chunzhe

VP of Huawei Cloud Core Network Marketing Dept.

04

5G is transforming China’s mining industry

Other mines in China are seeing similar benefits from deploying 5G. Huawei was also involved in the installation of a 5G network at the Xinyan Coal Mine of Lvliang Dongyi Group Coal Gasification Co., which is located in Lyuliang, in the Shanxi province. The underground mine, which has annual capacity is of 2.4 million tonnes, is spread over an area of 19.6 km2.

The mine, which adopted 5G in August 2020, has full underground 5G coverage, enabled by China Mobile and Huawei. It is using the connectivity to support nine core production systems, including a chairlift system, inspection robots, a wire rope flaw detector, a winch system, a trolley mining locomotive, data transmission, and remote control.

For example, five 5G inspection robots are deployed under and above ground to monitor the belt conveyors in the main inclined shafts, central substation and pump houses, winches for main and auxiliary shafts, chairlifts and other systems. The 5G connectivity also enables a central command and control centre above ground to remotely control shearers, scraper chain conveyors, and transportation belts.

Huawei says remote control of the shearer and roadheader requires connectivity with a latency of less than 50 ms. Furthermore, collecting real-time data and HD video streams from sensors and cameras at the mining face can require network capacity of up to 1 Gbps at the mining face, which is monitored by more than 70 cameras.

Similarly, the 5G connectivity is enabling remote driving of a trolley locomotive above ground and three trolley locomotives underground. It is also used to schedule and manage the mining, excavation, electro-mechanical, transportation and ventilation systems, and water, fire, gas, and roof conditions, while supporting decision-making, dispatch and command, and real-time control. As a result, the number of workers that need to be at the mining face has been halved from 130 to 65.

Huawei says 5G can also be used to enable unmanned haulage trunks to operate for up to 22-23 hours a day, increasing production efficiency by over 10%. The connectivity could even be used to enable field engineers wearing augmented reality glasses to interact with a remote knowledge base or experts to improve equipment maintenance and inspection efficiency.

05

Exploring opportunities in the oil, gas and chemical industries

The Yanjiahe Coal Mine’s 5G network was developed using China Unicom's One Cloud platform, which harnesses the operator’s core network to help meet the stringent reliability requirements of high-value industries. “This solution benefits both the operator and enterprises,” says [Chen Dan – 5G Industry Director of China Unicom 5G B2B Dept.]. “For China Unicom, the network functions on the public 5G core network can be fully utilised, while the enterprise customer benefits from the operator’s existing resources, expertise and experience. That reduces operating costs, while allowing the 5G private network to be set-up quickly.”

At MWC22 in Barcelona in February 2022, China Unicom and Huawei officially released the Kite-Like PNI-NPN solution. China Unicom has plans to apply the solution in more than 100 mine projects, while also exploring how the solution can support the oil, gas and chemical sectors, which can also operate in hazardous environments.

Huawei and Unicom are confident the Kite-Like PNI-NPN solution will help more and more enterprises address their increasingly strict requirements on service continuity and reliability. The two companies are working with industry standards organisations to standardise the 5G industry private network solution and promote its application on a larger scale.

Huawei and Unicom also plan to keep improving the solution’s capabilities by further exploiting the synergies between connectivity and computing. They expect more and more enterprise apps to be located at the edge of the network to provide local services.

“With on-premises edge compute, the solution enables local breakout, restricting data to within enterprise campuses for low latency and high security,” says [Chen Dan – 5G Industry Director of China Unicom 5G B2B Dept.]. “In addition, the solution can also meet enterprises' requirements on network construction costs as well as custom operations and maintenance. These advantages make the solution an ideal choice for a wide range of fields, such as open pit mining, well mining, oil and gas, as well as chemical industries.”

Chen Dan

5G Industry Director of China Unicom 5G B2B Dept.

06

About

About the GSMA

The GSMA is a global organisation unifying the mobile ecosystem to discover, develop and deliver innovation foundational to positive business environments and societal change. Our vision is to unlock the full power of connectivity so that people,

industry, and society thrive. Representing mobile operators and organisations across the mobile ecosystem and adjacent industries, the GSMA delivers for its members across three broad pillars: Connectivity for Good, Industry Services and Solutions, and Outreach. This activity includes advancing policy, tackling today’s biggest societal challenges, underpinning the technology and interoperability that make mobile work, and providing the world’s largest platform to convene the mobile ecosystem at the MWC and M360 series of events.

For more information, please visit the GSMA corporate website at www.gsma.com.

Follow the GSMA on Twitter: @GSMA.

GSMA 5G Transformation Hub

The GSMA 5G Transformation Hub is a source of information on some of the most innovative 5G solutions in the world. This portal contains case studies detailing design, benefits, key players, measured value and the future impact of scaling up these 5G solutions worldwide. The 5G Era is now firmly established and this family of standardised GSM technologies, including mmWave, are being rolled out successfully across the globe. The GSMA 5G Transformation Hub, launched at MWC Barcelona in 2022, provides details of how 5G is best placed to deliver real value for a range of key sectors including manufacturing, energy, transportation, media and live entertainment, smart cities and construction.. Many more case studies will be added, in the coming months, covering even more industries and the GSMA is asking Members to nominate innovative 5G case studies to add to this global digital showcase. The 5G Transformation Hub and this particular Case Study are both sponsored by Qualcomm.

About this case study

This case study is for information only and is provided as is. The GSM Association makes no representations and gives no warranties or undertakings (express or implied) with respect to the study and does not accept any responsibility for , and hereby disclaims any liability for the accuracy or completeness or timeliness of the information contained in this document. Any use of the study is at the users own risk and the user assumes liability for any third party claims associated with such use.