5G Transformation Hub

5G-enabled automated mining: bringing safety and productivity to harsh environments

China Mobile

Pangang Group Mining operates in Panzhihua-Xichang, one of China’s most mineral and iron-rich regions. To improve operational efficiency and working conditions, the Group has deployed a 5G network and edge computing solution which has helped to modernise conventional mining equipment, data centres and control systems.

Select a project

Contents

Challenge

Current surface mining and transportation processes rely heavily on humans undertaking hazardous operations in harsh operating environments. Attempts to improve circumstances have hitherto resulted only in temporary or siloed improvements – what’s needed is wholescale, system-wide enhancements covering wide areas and compatible with the industry equipment required.

Solution

Pangang deployed remote, intelligent surface mining and automated transportation systems which use 5G networks and 5G edge data centres to feed data through to smart remote-control centres.

Impact & Statistics

The project has achieved pronounced improvements in safety and productivity, and has been expanded to achieve full coverage across other mines such as Panzhihua, which by 2023 will have connected 16 drilling rigs, 23 electric shovels, and 27 mining trucks, and in Baima, which is expected to be fully connected by 2024.

Wider Implications

The project serves as a model for how to integrate mine engineering technologies with network communication and information technologies, featuring complicated and systematic operations.

Stakeholders

China Mobile, Huawei, Chuangyuan HiTech, and Boonray Technology

02

5G-enabled automated mining: bringing safety and productivity to harsh environments

Implementing 5G in the Pangang mine

The 5G solution needed to cover a wide area, support mobile equipment and applications, and be able to adapt to the harsh, complicated, and unstable scenarios typical of mining. Existing wired and wireless technologies have all found difficulty in meeting these business requirements – so instead of helping, the underlying supporting network for wireless transmission can become a bottleneck. As such, the new solution needed to serve the business goals of low latency, high upload throughput, strong reliability, and high security requirements. 5G terminal-side access needed to include automated components such as sensing devices, cameras, controllers, and industrial control computers, as well as network access devices such as AR routers and 5G CPEs.

The overall 5G network is composed of these 5G terminal-side access devices, the 5G wireless network, the 5G bearer network and the 5G core network. The 5G network refers to the 5G base stations and their wireless coverage over the mine enabling real-time connections between mobile devices in the area. The 5G bearer network adopts FlexE physical isolation and VPN logical isolation to ensure business security, and a ring networking mode is used to realise strong reliability. The 5G core network includes mining area MEC and the operator's 5GC network. This is supported by MEC which is deployed in integrated cases and cabinets of 5G edge data centres to ensure low-latency access of mining businesses in the mining area.

A private network environment has been created to provide 5G network planning design and analysis services, as well as basic debugging and testing, while network maintenance services ensure proper transmission of related data and control commands, so as to lay a foundation for further connectivity of mining equipment and data. The solution ensures data security by covering the mining face with 5G networks, building edge UPF on the mine layer, and connecting to the Pangang UPF as backup.

The effect of all this has been to transform a conventional industrial operation into a state-of-the-art solution which is now capable of remote and intelligent drilling, mining, and transportation equipment in open-pit mines – all of which are connected by enhanced-mobile broadband. These operations support HD video uplink to assist with remote control of working equipment and unmanned vehicles, which can be performed reliably and with low latency. Overall, implementation of 5G has helped the company transition to automated processes, putting staff at less risk.

03

The transformational impact of 5G

The 5G solution has had immediate impact on many areas of the mining operation in several specific ways:

5G edge data centre construction

The 5G edge data centres integrate 5G networks with underlying software and hardware resources for edge computing, to meet the systemic requirements for production data communication security, and further support applications related to the intelligent control system.

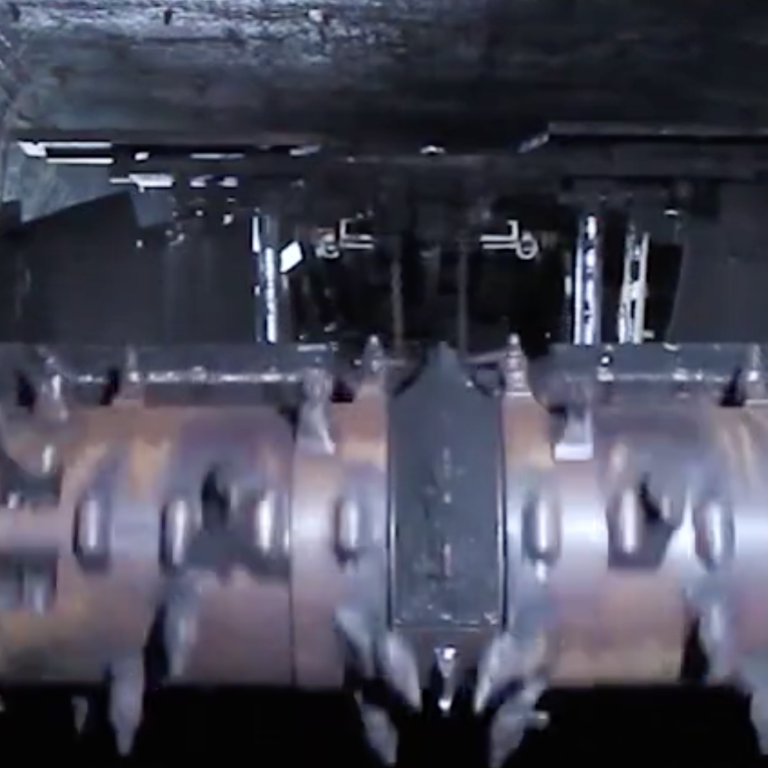

Rotary drills

After undergoing renovation, the mine’s rotary drills can be configured as needed to achieve precise depth measurement and positioning, and now automatically balance, find holes, change rods, and detect faults, which significantly improves on otherwise manual processes.

Electric shovels

The control-by-wire unit of electric shovels was renovated first to enable remote control, so that electric shovels can receive the control signals sent by the computer and send the necessary data generated to the remote control cabin.

Mining trucks

Trucks were renovated to enable network-based intelligence which spans environmental monitoring, intelligent algorithm support, integrated positioning, obstacle detection and safety monitoring. Although the vehicles are now highly automated, the operator can remotely take over the driving control system at any point.

04

Remote control and autonomous driving systems

Remote control systems are connected to electric shovels, the rotary drills, and the remote-control and autonomous driving systems. These collect real-time information including locations, statuses, monitoring, early warning task scheduling, and many other newly-enabled functions. In tandem, these functions form a stable and reliable intelligent mining system. The system features an interface which can be easily managed and connected to external mine truck scheduling.

The system also features highly accurate 3D diorama map the mining area which is formed and updated by automated photography drones. These greatly assist with overall operation and relay current real-time locations, operating statuses and other data of equipment. Geolocation and status are further enhanced by a GNSS positioning system which relies on positioning and navigation satellite systems including GPS, BeiDou, GLONASS, and Galileo, as well as RTK positioning base stations to provide high-precision positioning and orientation. The overall safety monitoring system provides real-time status parameters of various vehicles, shovels, and drills, and to issue alarms in time in the event of any abnormalities. The remote-control system can also be used with AR/VR technology to assist with remote detection.

The control centre is equipped with a remote cockpit to receive real-time data of all equipment and autonomous driving systems. The centre stores and analyses the data and presents visualisations of results to help improve remote control and scheduling.

05

Why should other businesses follow this example?

This project can serve as a guide for organisations in the mining sector seeking to integrate mine engineering technologies with network communications, information technologies and legacy systems. This project can serve as a guide for organisations in the mining sector seeking to integrate mine engineering technologies with network communications, information technologies and legacy systems.

There is much to be studied across a range of disciplines such as core networks, information management and application layers. There is a high degree of complexity not just in the execution of each discipline, but also in coordinating them and their respective organisations. In terms of system construction, 5G technologies are applied at the network layer, requiring input from network communication technology companies. In terms of the equipment renovation and remote-control and autonomous driving application at the physics layer, suitable external units should be selected to participate in the process. A team with strong capabilities in system integration and management is essential for such a systematic engineering project.

The capabilities of core partners are the key to the performance of cross-sector integration and the success of the project. In light of the current trends for ‘green, smart, and unmanned’ mines, the project team kept optimising and improving the applications in related scenarios while providing support with the underlying transmission network and edge computing resources of the mine for connectivity of mining equipment and data.

06

Summary and next steps

The project provided numerous benefits to the Pangang mining operation including the fulfilment of their objectives to have a ‘one-click operation’ and remote-control capabilities. By using a cloud host and network slicing, the operation is able to reinforce the functional and network security of edge terminals to enhance application security. Likewise, other network innovations such as cloud gateway and new data management platforms have resulted in much more effective use of data.

The project has also enabled the mine to make use of wind power and PV applications in mines to help reduce its carbon footprint and digital management of energy.

The success of the project has resulted in its emulation at other sites including another at Panzhihua and also Baima. Pangang aims to achieve full coverage across the Panzhihua iron ore site with 16 drilling rigs, 23 electric shovels, and 27 mining trucks by 2023 and full coverage of Baima iron mine by 2024. Following these successes, the company is examining how 5G networks and their related systems can be applied to another mine in Honggenan.

07

About

About the GSMA

The GSMA is a global organisation unifying the mobile ecosystem to discover, develop and deliver innovation foundational to positive business environments and societal change. Our vision is to unlock the full power of connectivity so that people,

industry, and society thrive. Representing mobile operators and organisations across the mobile ecosystem and adjacent industries, the GSMA delivers for its members across three broad pillars: Connectivity for Good, Industry Services and Solutions, and Outreach. This activity includes advancing policy, tackling today’s biggest societal challenges, underpinning the technology and interoperability that make mobile work, and providing the world’s largest platform to convene the mobile ecosystem at the MWC and M360 series of events.

For more information, please visit the GSMA corporate website at www.gsma.com.

Follow the GSMA on Twitter: @GSMA.

GSMA 5G Transformation Hub

The GSMA 5G Transformation Hub is a source of information on some of the most innovative 5G solutions in the world. This portal contains case studies detailing design, benefits, key players, measured value and the future impact of scaling up these 5G solutions worldwide. The 5G Era is now firmly established and this family of standardised GSM technologies, including mmWave, are being rolled out successfully across the globe. The GSMA 5G Transformation Hub, launched at MWC Barcelona in 2022, provides details of how 5G is best placed to deliver real value for a range of key sectors including manufacturing, energy, transportation, media and live entertainment, smart cities and construction.. Many more case studies will be added, in the coming months, covering even more industries and the GSMA is asking Members to nominate innovative 5G case studies to add to this global digital showcase. The 5G Transformation Hub and this particular Case Study are both sponsored by Qualcomm.

About this case study

This case study is for information only and is provided as is. The GSM Association makes no representations and gives no warranties or undertakings (express or implied) with respect to the study and does not accept any responsibility for , and hereby disclaims any liability for the accuracy or completeness or timeliness of the information contained in this document. Any use of the study is at the users own risk and the user assumes liability for any third party claims associated with such use.