5G Transformation Hub

Intelligent manufacturing at the edge via private 5G networks

Private 5G for security, reliability and speed

Collaboration between ZTE Nanjing and China Telecom has yielded a state-of-the-art electronics factory at ZTE’s Binjiang site, with 5G-enabled processes in place at almost every level of operation, via integration of information technology and operational technology supported by ZTE’s private 5G network. By November 2021, the ZTE Global 5G Intelligent Manufacturing Base at Binjiang had implemented more than 30 5G convergence application scenarios and deployed more than 400 5G industry terminals, with peak real-time enterprise data offloading reaching 4Gbps.

Select a project

Contents

Challenge

Fragmented legacy IT systems and inadequate manpower, coupled with complex production processes and demand for very large unit volumes, made the need for digital reform at ZTE’s Binjiang site extremely pressing: a ‘flexible factory’ was required, based on lean, automated manufacturing processes and intelligent management to enhance competitive advantage and boost production efficiency.

Solution

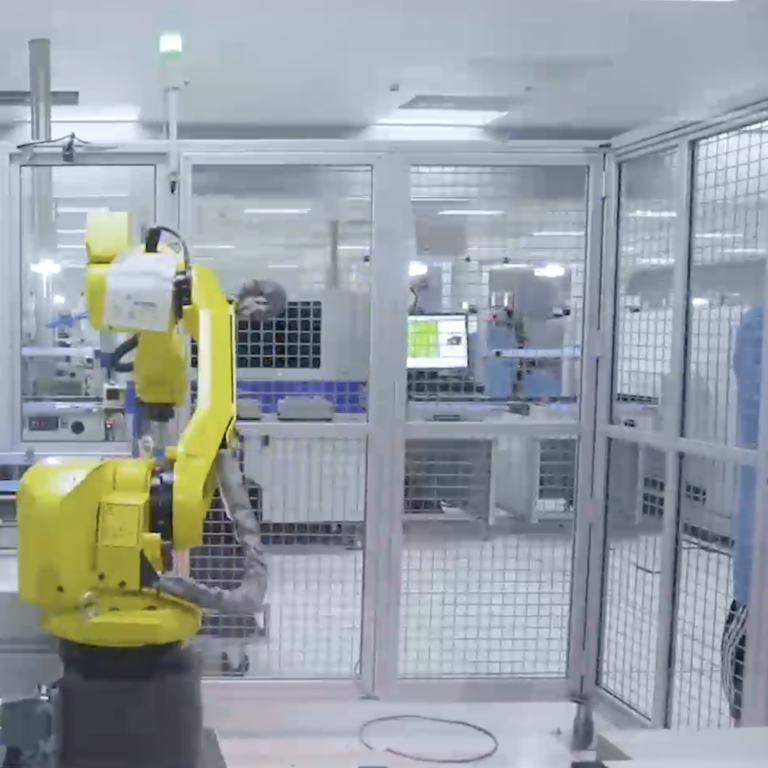

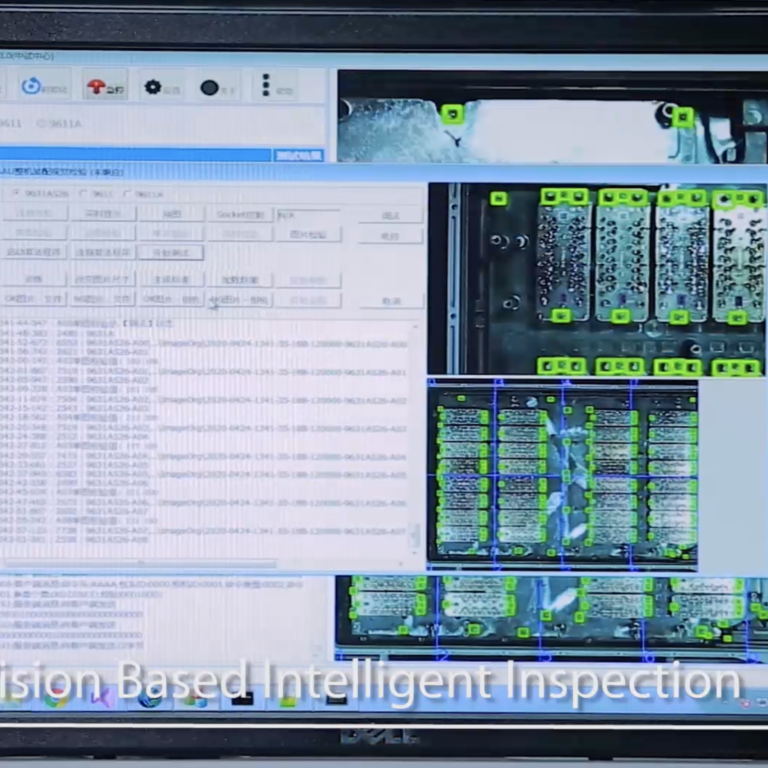

Enhancements included 70 5G-navigated AGVs to deliver materials automatically using smart warehousing. Machine vision is also used, for instance in quality inspections, via hi-definition images processed at the edge. Other improvements included remote control of production processes using 4K video streaming, 5G robots for line patrols and problem solving, cloud-based knowledge libraries for remote decision-making in maintenance, and intelligent analysis of surveillance data for early warning generation.

Impact & Statistics

ZTE’s smart manufacturing practices at Binjiang have yielded significant benefits in cost reduction, quality improvement and efficiency: an 80% decrease in the rate of missed inspections of assembly quality, a 46% reduction in the defectiveness rate of key processes, a 28% cut in the need for production line personnel, and a 20% shorter adjustment cycle on the production line.

Wider Implications

: Interest in 5G for IIoT innovations has skyrocketed. As of November 2021, the Binjiang factory has welcomed more than 500 enterprises and institutions over more than 10,000 visits, showcasing its flagship demonstration of 5G’s role in connected industry. Building on the results at Binjiang, ZTE has deployed 100+ innovative 5G application scenarios for 60+ clients with significant social impact.

Stakeholders

ZTE Nanjing and China Telecom

02

Private 5G for security, reliability and speed

ZTE’s starting point was a focus on informatisation targeted at breaking data silos via integration of 5G, cloud and IIoT systems - promoting digital transformation of operational technology to achieve smart equipment, digital manufacturing, and intelligent operations. 5G’s low latency and high reliability were among the key necessary enablers of these processes, and a private network was required to meet the need for visibility, governance and control, and security requirements of keeping data onsite. So, as of December 2021, a total of 10 outdoor macro base stations and 751 indoor distribution nodes had been built, covering the entire factory premises.

The factory’s industrial 5G-navigated AGVs for instance have much greater connection stability with 5G than under Wi-Fi, and can render cloud-based maps as well as monitoring and responding to needs in real time by coordinating with inventories via the 5G network. High-bandwidth 5G connectivity enables wireless transmission of ultra-high-definition videos to mobile terminals to enable remote production management. Precise control of industrial equipment in production facilities is achieved from the control centre using panoramic HD videos from the production environment and data from various types of terminals in real time.

The introduction of 5G also makes the end-to-end industrial machine vision system more flexible, convenient and scalable, by allowing the considerable computing capacity required by multi-point machine vision applications in the factory to be flexibly allocated and coordinated using GPU virtualisation. Deep learning can then be performed to improve recognition, transforming production lines to reduce labour costs and improve both efficiency and product quality.

On-site data such as images, videos and audio are transmitted in real time to help onsite operators carry out assembly and maintenance of complex or delicate equipment. This guidance system is powered by 5G, allowing 4K ultra-high-definition video to connect front-line operators with a cloud-based knowledge library, and enables experts to access guidance on the maintenance of SBCs remotely in real time, improving communication efficiency and maintenance accuracy.

5G inspection robots and drones were also launched to replace personnel patrols, and the optimisation of 5G network coverage in high-altitude and open environments allows real-time video and other related data to be sent back to the industry park management platform through the 5G network.

03

Digital twinning for smart interconnection

ZTE’s self-developed IIoT cloud platform based on digital twin technology achieves intelligent interconnection of equipment, real-time data collection and processing, and automated analysis of working condition protocols, enabling efficient data sharing and eliminating data silos to form a data pool. It also provides data and application support to industrial applications such as digital twinning and predictive maintenance of production lines and premises, factory vehicle management, energy consumption monitoring and analysis.

ZTE was the first to launch a production line-ready 5G cloud-based PLC on the test production lines for a small base station at the Binjiang Intelligent Manufacturing Base. The control logic of the PLC runs on the MEC side, and the IO module is deployed onsite to form a cloud-based PLC solution that can replace multiple traditional hardware PLCs. Free from the limits of traditional PLC hardware, programming environments and interface protocols, 5G cloud-based PLC supports cloud-based graphical programming, unified control, offline simulation, multiple protocol support, and more flexible expansion to make production lines more intelligent and flexible.

04

The results: efficiency and output soar

ZTE’s 5G applications at Binjiang were so successful in cost reduction and efficiency that they helped annual output in 2021 to exceed CNY 30 billion – 50% above target – a clear demonstration that combining 5G and intelligent manufacturing has immense value potential for industry.

The 5G-navigated AGVs yielded a 20% efficiency increase in cargo turnover, a 15% reduction in site construction cost, 100% manpower savings, and a reduction of more than CNY 2 million in labour costs. The remote expert guidance system reduces the need for business travel by 30%, and lowers maintenance response times from a magnitude of days to hours.

Compared with traditional hardware PLCs, the 5G cloud-based PLC improves efficiency for operation and maintenance and reduces turnaround time for production line changes by more than 20%. With extensive tuning of the 5G network, and leveraging technologies such as NodeEngine and MCS enhancement, the solution can maintain latency below 12ms, and reduce the fault rate to no more than two per month.

A single 5G inspection robot can accomplish the equivalent of three to four people’s workload – through intelligent analysis via the cloud and real-time early warnings, these devices present considerable potential for improvement of operation and management capabilities.

05

Building on Binjiang’s strengths and enhancing collaboration

ZTE plans to replicate Binjiang's practices in other factories – while also accelerating integration vertically into different application scenarios – developing more ‘dark factories’ with 5G as the driving force and technical enabler, with the aim of increasing its share of total factory capacity from 26.1% to more than 80%.

ZTE also plans to use the experience gained to empower the wider industrial ecosystem to digitalise and transform intelligently. Through the Binjiang Industrial Internet Innovation Centre, ZTE provides an environment for partners to conduct R&D of industrial applications, as well as testing at ZTE’s Nanjing factory, allowing its success in digital transformation at Binjiang to be shared and used by other stakeholders and partners.

Collaboration with China Telecom has also resulted in a 5G industrial Internet application supermarket to speed up the promotion of successful new infrastructure projects, with the aim of incentivising enterprises to embrace 5G and explore innovations based on 5G private networks.

Through ZTE’s growing mastery of connectivity assurance, data value extraction, and ecosystem partnerships, the company aims to establish a prosperous and healthy ecosystem with its industry partners, so that they too can benefit from 5G-powered digital transformation, safeguarding the healthy development of 5G IIoT.

06

About

About the GSMA

The GSMA is a global organisation unifying the mobile ecosystem to discover, develop and deliver innovation foundational to positive business environments and societal change. Our vision is to unlock the full power of connectivity so that people,

industry, and society thrive. Representing mobile operators and organisations across the mobile ecosystem and adjacent industries, the GSMA delivers for its members across three broad pillars: Connectivity for Good, Industry Services and Solutions, and Outreach. This activity includes advancing policy, tackling today’s biggest societal challenges, underpinning the technology and interoperability that make mobile work, and providing the world’s largest platform to convene the mobile ecosystem at the MWC and M360 series of events.

For more information, please visit the GSMA corporate website at www.gsma.com.

Follow the GSMA on Twitter: @GSMA.

GSMA 5G Transformation Hub

The GSMA 5G Transformation Hub is a source of information on some of the most innovative 5G solutions in the world. This portal contains case studies detailing design, benefits, key players, measured value and the future impact of scaling up these 5G solutions worldwide. The 5G Era is now firmly established and this family of standardised GSM technologies, including mmWave, are being rolled out successfully across the globe. The GSMA 5G Transformation Hub, launched at MWC Barcelona in 2022, provides details of how 5G is best placed to deliver real value for a range of key sectors including manufacturing, energy, transportation, media and live entertainment, smart cities and construction.. Many more case studies will be added, in the coming months, covering even more industries and the GSMA is asking Members to nominate innovative 5G case studies to add to this global digital showcase. The 5G Transformation Hub and this particular Case Study are both sponsored by Qualcomm.

About this case study

This case study is for information only and is provided as is. The GSM Association makes no representations and gives no warranties or undertakings (express or implied) with respect to the study and does not accept any responsibility for , and hereby disclaims any liability for the accuracy or completeness or timeliness of the information contained in this document. Any use of the study is at the users own risk and the user assumes liability for any third party claims associated with such use.