5G Transformation Hub

5G Ushers in New Era for Manufacturing

Comprehensive 5G network lowers labour costs by 30% in new washing machine factory

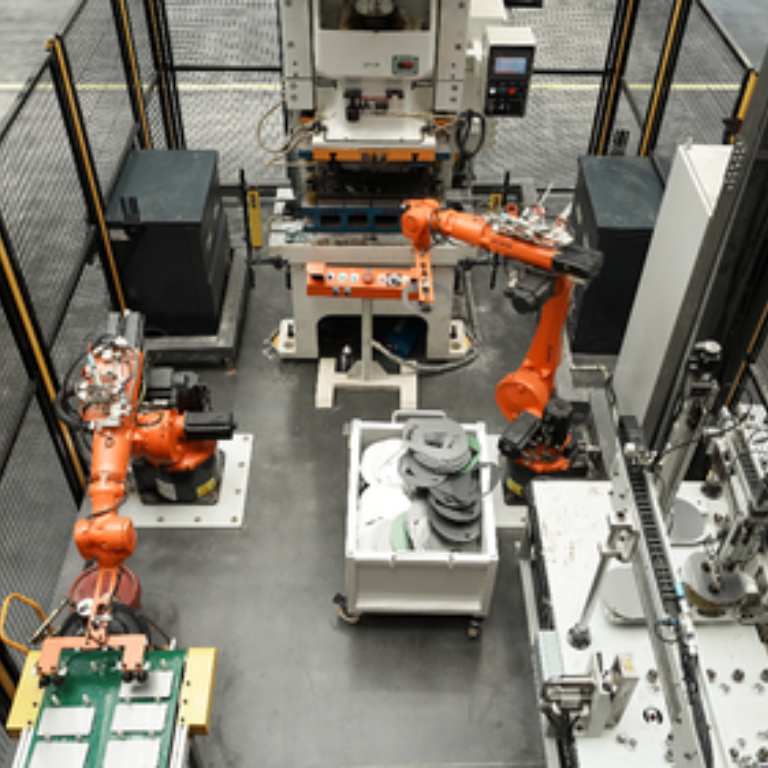

In Jingzhou, Hubei Province, Midea has opened a new washing machine factory that uses 5G to deliver a fully interconnected manufacturing process. Built by China Mobile and Huawei, the factory-wide 5G network enables end-to-end digitisation, advanced logistics, automated robotics, real-time production line monitoring and quality checks using artificial intelligence.

Select a project

Contents

Challenge

Large manufacturing plants tend to rely on numerous fibre-optic network cables and Wi-Fi routers to connect equipment, resulting in high costs, long deployment periods and inflexible infrastructure that is difficult to upgrade or expand. As Wi-Fi networks operate in unlicensed spectrum, they can be subject to interference, meaning that automated guided vehicles (AGVs) and other connected equipment can be impacted by unstable signals.

Solution

Midea is using the factory-wide 5G network (encompassing 2,500 connected devices) to collect real-time process data, which is analysed by the manufacturing execution system. That analysis is used to continually optimise the entire production process. Controlled in the cloud, 5G-connected robots and AGVs can easily be redeployed and reconfigured, thereby making the production lines more flexible, and helping to streamline the supply, production, distribution, warehousing and shipment processes across the plant. The factory also uses 5G-connected sensors, instruments and cameras to help it manage energy consumption, track environmental factors, improve safety and maintain site security.

Impact & Statistics

At the new factory, a washing machine comes off the production line every 15 seconds, which is three seconds faster than the next fastest factory in the industry, according to Midea. Compared with a traditional washing machine factory in the Midea Group, the production rate has been doubled, the inventory has been reduced by 50%, and the production cost per product has been cut by 30%. Midea says it has achieved quality improvements, while making the factory safer and more sustainable.

Wider Implications

Huawei says China’s government is encouraging the manufacturing sector to deploy thousands of 5G-enabled factories, as part of a programme that will run between 2021 and 2025. The widespread adoption of 5G in the manufacturing sector could bring major social and environmental benefits, by improving the operational efficiency of factories that tend to use substantial amounts of resources and energy.

Stakeholders

Midea , China Mobile and Huawei

02

5G Ushers in New Era for Manufacturing

Comprehensive 5G network lowers labour costs by 30% in new washing machine factory

In Jingzhou, Hubei Province, Midea has opened a new washing machine factory that uses 5G to deliver a fully interconnected manufacturing process. Built by China Mobile and Huawei, the factory-wide 5G network enables end-to-end digitisation, advanced logistics, automated robotics, real-time production line monitoring and quality checks using artificial intelligence.

At the new factory, a washing machine comes off the production line every 15 seconds, which is three seconds faster than the second fastest factory in the industry, according to Midea. Compared with a traditional washing machine factory in the Midea Group, output has been doubled, the inventory has been reduced by 50%, and the production cost per product has been cut by 30%. Midea says it has achieved quality improvements, while making the factory safer and more sustainable.

Midea uses 5G's low latency and multi-access edge computing to collect data on the factory’s processes, which is analysed by the manufacturing execution system. That analysis can be used to make predictions and subsequently optimise the entire manufacturing process. Controlled in the cloud, 5G-connected robots and automated guided vehicles (AGVs) can easily be redeployed and reconfigured, thereby making the production lines more flexible, and helping to streamline the supply, production, distribution, warehousing and shipment processes across the plant. Midea’s new factory also uses 5G-connected sensors, instruments and cameras to help it manage energy consumption, track environmental factors, increase safety and maintain site security.

When it went live in August 2022, Midea’s new factory had 2,500 5G connections and more than 1,000 automated machines (in the production and logistic lines). “Each production phase is seamlessly connected through 5G terminals with faster automated machine operations that streamline the complex workshop pipelines,” says [wang Liang] of Midea. “It is a benchmark not only in Midea Group, but also in the home appliance manufacturing industry.”

Midea’s holistic deployment of 5G marks a complete departure from the traditional approach to connecting a factory, in which a large number of fibre-optic network cables and Wi-Fi routers are installed, resulting in high costs, long deployment periods, and inflexible infrastructure that is difficult to upgrade or expand. Noting that 5G is more reliable than Wi-Fi, Midea says its AGVs and other connected equipment are less likely to be impacted by unstable signals.

The decision to build 5G into the factory from the start has also saved time and money. China Mobile estimates this approach reduced the whole construction period by at least 60 days. “Traditionally, communication networks are not rolled out until a factory and production lines are completed, which can be a lengthy process, and hence does not meet client expectations,” says [Zhang Fei] of China Mobile. “China Mobile wanted to find a faster way to accomplish this.”

China Mobile used a combination of macro sites, pole sites and Huawei’s LampSite solution to build an indoor and outdoor massive MIMO 5G network, which operates in the 2.6 GHz and 4.9 GHz bands. Huawei says the end-to-end reliability of the 5G network, which has a total uplink capacity of 7 Gbps, is over 99.99%, thanks to the redundancy built into its multi-level design. The network also delivers 1Gbps uplink capacity per square kilometre in dense areas, Huawei adds. The distributed massive MIMO technology uses frequency spatial multiplexing and uplink multi-layer transmission to increase capacity. China Mobile and Huawei have also developed algorithms to enhance pairing and reduce interference between terminals and base stations, to further boost uplink capacity by 20%.

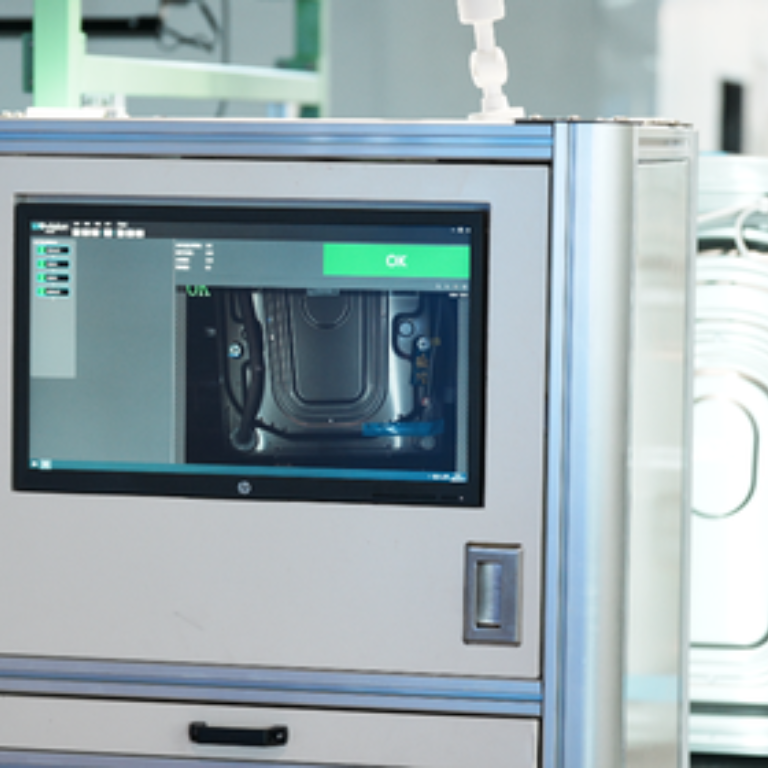

The high capacity 5G uplink enables Midea to capture HD images in real-time from multiple angles. Analysed by AI algorithms, these images have improved the accuracy of the quality control system by 10%.

Before building the network, China Mobile and Huawei ran 3D modelling simulations in the cloud drawing on data from high-precision lasers to map out the real-world environment. “The modelling precision rate reaches 99% and the simulation matching degree rate exceeds 90%, ensuring the deterministic rate for each access terminal,” says [Eric Bao] of Huawei. This precision modelling helped to ensure the 5G network would meet Midea’s performance requirements.

Wang Liang

Director of Intelligent Manufacturing, Midea Laundry Appliance Department

03

Greater network resilience and security

In a fully connected factory, a minor network failure will affect production, while a severe failure could suspend production, which would have major financial consequences. Therefore, highly reliable connectivity is vital.

Huawei says its LampSite solution employs a three-layer design – a baseband unit (BBU), a radio remote unit HUB (RRU HUB), and a pico RRU (pRRU) – to maximise reliability. LampSite also uses the multilink redundancy technology of distributed massive MIMO. If a pRRU fails, the neighbouring pRRU can take over services from the disconnected module, ensuring operations aren’t interrupted. “According to a live test in this project, even if multiple modules fail, the network services will not be affected, preserving reliable operation in the entire factory,” says Eric Bao of Huawei.

The network also employs master-backup and multi-routing for base stations and transmission links to create redundancy and ensure no interruption in service. “Module-level and equipment-level redundancy backup planning ensures that any failure in the core network will not disrupt the services, and a single device failure can be restored in minutes,” adds Eric Bao of Huawei.

A mission-critical network also needs to be highly secure. The core network’s user plane function is deployed on premise in the factory to safeguard data security. At the same time, the air interface signalling is protected by using the advanced encryption standard AES256, SNOW 3G and other encryption algorithms to ensure data security, and by using end-to-end IPSEC encryption to ensure secured data transmission. In the access layer, terminal access authentication and two-way authentication are employed to prevent unauthorised connections.

Eric Bao

President of Digital Indoor System Product Line, Huawei

04

5G factories to become commonplace in China

China’s government is encouraging the manufacturing sector to deploy thousands of 5G factories, as part of a programme that will run between 2021 and 2025, according to Huawei.

Under the guidance of the Hubei Provincial Economic & Communications Bureau and Industrial Internet Industry Alliance, Midea, China Mobile and Huawei have developed and released official guidelines on building 5G networks and applications in the home appliance industry in Hubei. The guidelines are designed to improve the standard of construction, intelligence and digitalisation of a 5G fully-connected factory.

While building 5G smart factories, Midea continuously accumulates capabilities to build Midea's industrial IoT M.IoT system, attracting more than 20 partners, including 5G terminals, industrial equipment, application integration, and AI algorithms, and incubating multiple 5G hardware and applications. Drive the in-depth development of the industry chain. Currently, Midea M.IoT has been exported to more than 40 segmented industries, including more than 300 top customers. The 5G solution is a key capability of the overall solution and enables more partners.

The widespread adoption of 5G in the manufacturing sector could bring major social and environmental benefits by improving the operational efficiency of factories that tend to use a lot of resources and energy. Large-scale usage of 5G-connected devices, which benefit from a smart energy saving function, reduces the need for paper in the office, production line and logistics. “Once the production capacity of the factory increases, the power consumption for manufacturing a single washing machine can be reduced by as much as 15%,” says [Wang Liang] of Midea.

There are also potential safety benefits. In a traditional factory, a lot of optical fibres, network cables and electrical wires are deployed in the workshops, and this wiring can easily trip workers or even cause an electric shock. The use of 5G-connected video surveillance and environmental monitoring should also ensure a safer production environment for workers and suppliers.

At the same time, staff should enjoy better working conditions. Thanks to 5G connectivity, employees can manage the production operations remotely in a quiet air-conditioned room. The time saved through the resulting operational efficiency improvements also enables workers to focus on more highly skilled and satisfying work.

05

Major expansion planned for 2023

Midea has plans to expand the capacity of the Jingzhou factory in 2023: two more production lines will completed in the second phase of the project, and the number of connected 5G terminals will then exceed 8,000.

This expansion will require some 5G terminals to be reallocated, as well as changes to the network capacity requirements in the workshop. Distributed massive MIMO technology makes these adjustments easier. “There is no need to move the modules, as the technology can dynamically match the changes of the production line, by providing a deterministic rate and capacity,” says Eric Bao of Huawei. “Distributed massive MIMO cells can also be split to form an extremely-large distributed massive MIMO cell easily to achieve 3Gbps uplink capacity per 10,000m2, with 100MHz bandwidth spectrum.”

A distributed massive MIMO solution can be used to define a consistent capacity per unit area of the factory, which is more intuitive for an industrial customer purchasing network capability, than network capacity defined by cell. This feature makes wireless network planning as simple and flexible as building blocks, according to Huawei. “To match up with the future requirements for vertical industries, the solution can be easily upgraded to support mmWave transmission, high-precision positioning, advanced intelligent sensing, etc.” adds Eric Bao of Huawei.

As most manufacturing sectors have similar service requirements, Huawei anticipates that the solution deployed by Midea can be replicated on a large scale across the industry. With more and more fully-connected factories, China (and the rest of the world) could take one step closer to carbon neutrality and a more sustainable future.

Eric Bao

President of Digital Indoor System Product Line, Huawei

06

About

About the GSMA

The GSMA is a global organisation unifying the mobile ecosystem to discover, develop and deliver innovation foundational to positive business environments and societal change. Our vision is to unlock the full power of connectivity so that people,

industry, and society thrive. Representing mobile operators and organisations across the mobile ecosystem and adjacent industries, the GSMA delivers for its members across three broad pillars: Connectivity for Good, Industry Services and Solutions, and Outreach. This activity includes advancing policy, tackling today’s biggest societal challenges, underpinning the technology and interoperability that make mobile work, and providing the world’s largest platform to convene the mobile ecosystem at the MWC and M360 series of events.

For more information, please visit the GSMA corporate website at www.gsma.com.

Follow the GSMA on Twitter: @GSMA.

GSMA 5G Transformation Hub

The GSMA 5G Transformation Hub is a source of information on some of the most innovative 5G solutions in the world. This portal contains case studies detailing design, benefits, key players, measured value and the future impact of scaling up these 5G solutions worldwide. The 5G Era is now firmly established and this family of standardised GSM technologies, including mmWave, are being rolled out successfully across the globe. The GSMA 5G Transformation Hub, launched at MWC Barcelona in 2022, provides details of how 5G is best placed to deliver real value for a range of key sectors including manufacturing, energy, transportation, media and live entertainment, smart cities and construction.. Many more case studies will be added, in the coming months, covering even more industries and the GSMA is asking Members to nominate innovative 5G case studies to add to this global digital showcase. The 5G Transformation Hub is sponsored by Qualcomm.

About this case study

This case study is for information only and is provided as is. The GSM Association makes no representations and gives no warranties or undertakings (express or implied) with respect to the study and does not accept any responsibility for , and hereby disclaims any liability for the accuracy or completeness or timeliness of the information contained in this document. Any use of the study is at the users own risk and the user assumes liability for any third party claims associated with such use.